Why $5? It took some effort to get this thing to work right. The information by way of pictures along with some very needed practical experience information will make everything clear as to how I did it and maybe keep you from hurting yourself or someone else.

How to tell if you have 220V single phase power in the first place? What does 220V single phase even look like?

Places to look for a 220V single phase outlet would be in a utility or laundry area where there is a close dryer. If you have 220V single phase, you will find a fairly large 3 inlet receptacle. The exact configuration will depend on the amperage of the circuit breaker in your fuse box. This will generally be a 30 amp service. Always use the correct plugs and receptacles that accommodate the supply voltage and amperage from your circuit breaker box. In the diagram below the R stands for the receptacle (female) and P stands for the plug (male). The number to the left of the P or R is the amperage. You can see what the various plug / receptacles look like for 250V - 20, 30, and 50 amp configurations. You must have 220V single phase power to run a 220V 3 phase motor.

You will need one of these receptacles somewhere in your house or garage. If you have one of these receptacles, you have 220V single phase power.

Video This video doesn't show much except to demonstrate that all you need is a properly wired idler motor in the circuit, and that's about it.

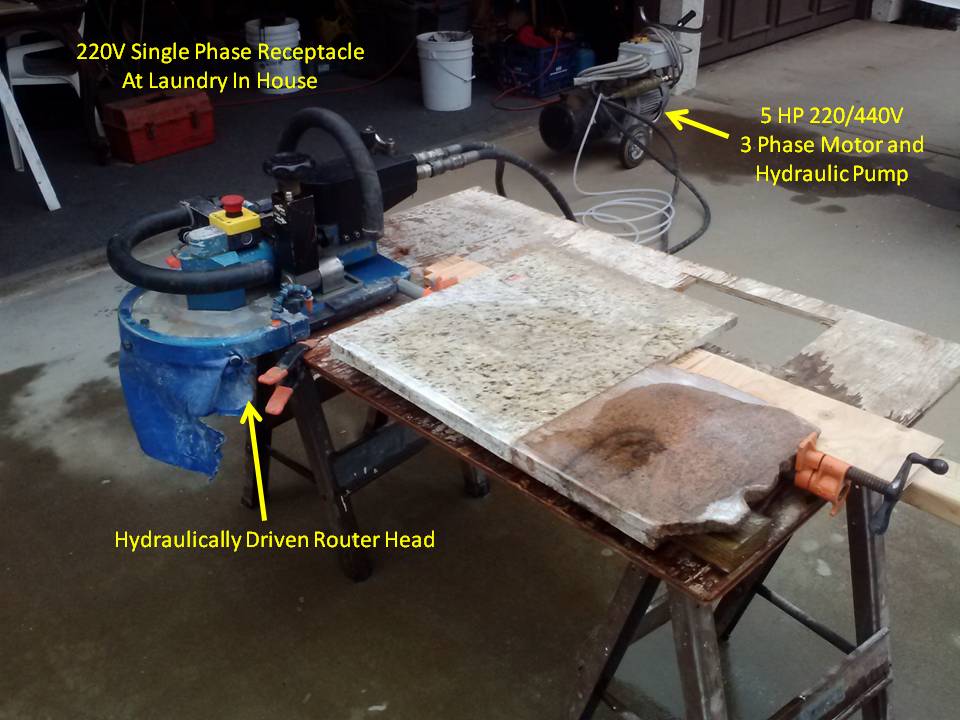

I needed to power a 4.8 HP 220/440V 3 phase motor that powers a hydraulic router head for profiling granite. The machine is a $5000 machine that was worthless because I could not power the motor. I didn't know anyone who had 3 phase power. Not even some of the shops I went to had 3 phase power. However, I did have 220V single phase power at my house and shop. I built a rotary converter and it powers the hydraulic routers 3 phase motor. The 3 phase motor does not get hot even when run for a long time. It starts easily and has full power. I would have gladly paid someone $100 to tell me how to do this when I first need to power a 3 phase electric motor with single phase power. I was initially looking at spending more than $1500 on a setup that I did not need.

Ay Caramba Colombia - Emeralds

Cambodia - Zircon and the Angkor Wat Temples

Link To Other Quality Websites